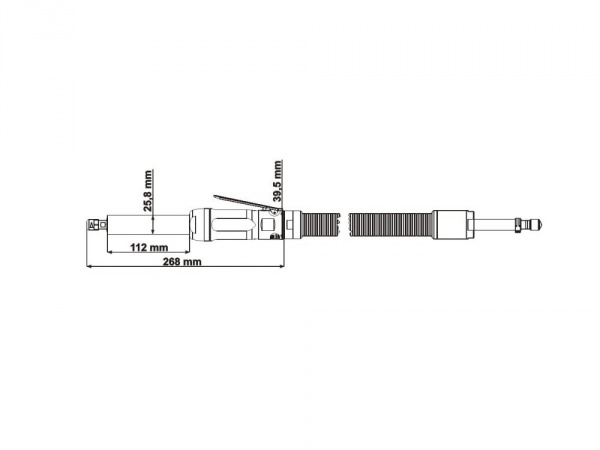

GDST050-550BXFO

Our pneumatic grinder fulfill all requirements for an optimum fabrication - optimum material removal using a carbide cutter (grinding insert) or grinding tip, for consistent and quality performance.

This midget grinder is used mainly for the treatment of plastic and metals in foundries, in the entire mechanical engineering industry, the tool- and die industry, the appliance-industry to level, de-burr or treat cast-iron parts.

Speed governor for optimal performance.

Your advantages: For industrial applications, high power-output at a low weight, highly durable, efficient, ergonomic, simple operation

Well balanced 6 mm collet (Standard Equipment). With frontal exhaust (partial). With supply/exhaust hose.

| Max. power output | 500 W / .67 hp |

|---|---|

| Speed (no load) | 55000 min-1 |

| Weight | 0,9 kg / 1.98 lbs |

| Drive | turbine drive |

| Assortment | Additional Assortment |

| Start | safety lever |

| Design | Basic Design, frontal exhaust (partial) |

| Rotation | right |

| Air consumption (no load) | 0,13 m3/min / 4.59 cfm |

| Air consumption (loaded) | 0,74 m3/min / 26.13 cfm |

| I.D. of air inlet hose | 10 mm / .39 in |

| Max. Ø of grinding tip | 16 mm / .63 in |

| Max. Ø of grinding insert | 12 mm / .47 in |

| Length of supply/exhaust hose | 2/1 m / 6.6/3.3 ft |

| Collets - clamping range | 6 [3; 4; 5; 1/8''; 3/16'';1/4''] mm |

| Air connection | Nipple |

| Operating pressure | 6,3 bar / 90 psi |